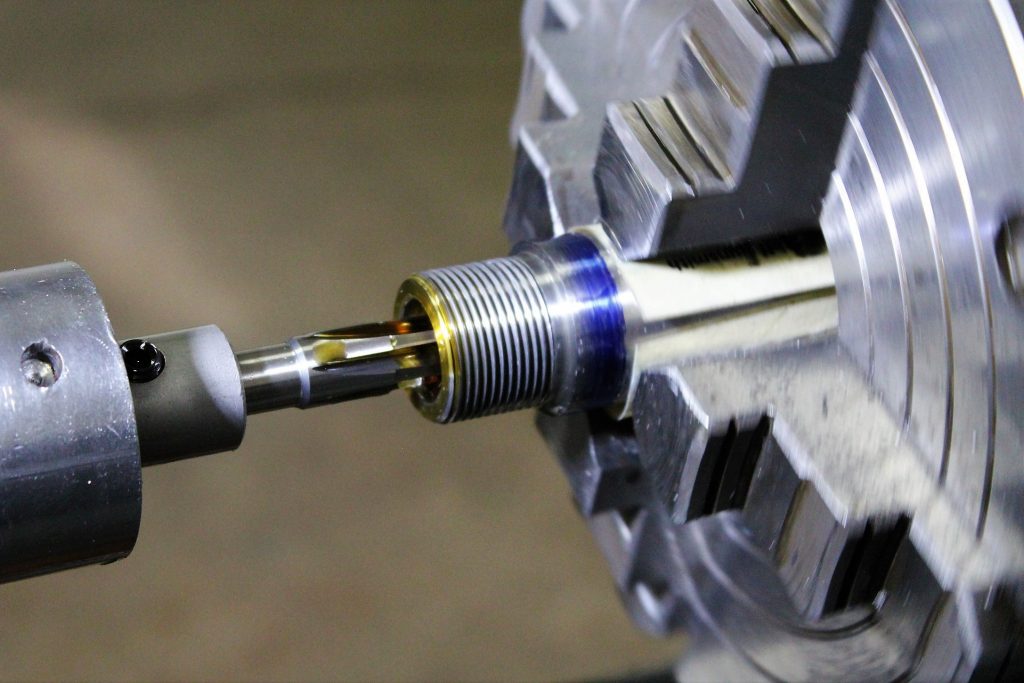

During Machine Shop students will be exposed to a wide variety of machining applications. Students start Machine Shop by grinding lathe bits from blank pieces of tool steel. Once this task is successfully completed students will be introduced to the engine lathe. Concepts that are learned on the engine lathe include turning, facing threading, chamfering and reaming. The lathe portion of the Machine Shop culminates in the student successfully threading, chambering, crowning and test firing a barreled action. Once complete with the engine lathe students then move on to the vertical milling machine. Skills and concepts learned on the milling machine include facing, pockets, sight cuts and drilling and tapping.

Students will then move to the CNC or Computer Numerical Control section of the Machine Shop. During this section both CNC mills and CNC lathes will be used to expose students to machine operations that are found within the Gunsmithing and Manufacturing areas of the Firearms Industry. While operating the CNC lathes students will grasp an understanding of turning, facing, drilling and tapping. Students will explore CNC milling procedures such as facing, pocketing, contouring, fixturing and thread milling.